The mechanical seal for the pump makes it possible to make the device more airtight in areas with a special risk of leaks, namely where the rotating drive shaft passes through the cover of the product. This is necessary when the pump actively interacts with toxic, flammable and poisonous liquids. The mechanical seal is particularly resistant to pressure, thanks to which it reliably protects the device from leakage.

How does the mechanical seal for the pump work?

The mechanical seal for the pump – is a part, the selection of which requires experience, qualification and analysis of activities. Incorrect product selection can lead to problems during operation and rapid wear. If you do not know which model will be optimal in your case, do not be afraid to contact us. We will provide you with high-quality advice and answer all your questions.

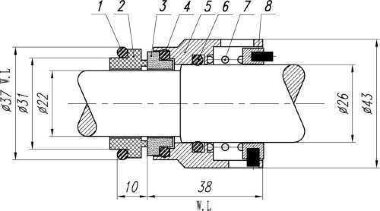

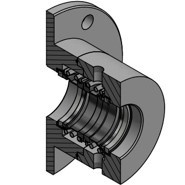

The mechanical seal for the pump, in short, has a complex structure consisting of two parts:

- Fixed, fixed in the device housing.

- Movable, fixed on the shaft of the device and constantly rotates with it, pressing against the stationary part with the help of springs.

There are several models of mechanical seals. The design in each of them is slightly different from each other, because it is designed to perform different tasks.

Basically, the basis of this product consists of two surfaces: movable and fixed. By all standards and norms, they are perfectly polished. The most common among them are graphite, silicon carbide and tungsten carbide.

The manufacturers of the product have done everything to ensure that its operation is long and of high quality. Each part is equipped with a special "liquid film" - the space between the movable and fixed elements in order to avoid too much friction.

Also, for proper, long-term and efficient operation of the device, it is necessary to choose the right alignment between the pump shaft and its motor. This will help to avoid rapid wear of the mechanical seal, even if the device is running at high power.

What are the mechanical seals for the pump?

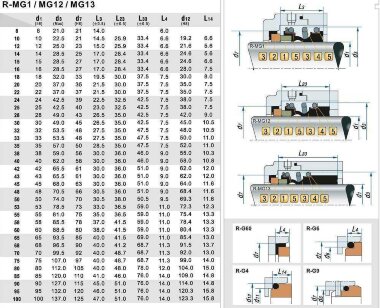

Here you can download the catalog of mechanical seals for the pump with the entire range of available models. In addition, we can carry out the selection according to the brand of the pump EMU, Ebara, FRISTAM, INOXPA, KOLMEKS, Leszczyńska Fabryka Pomp, GRUNDFOS, Lowara, PENTAX, SAER, SPERONI, WILO. Also available are parts for pumps of other models.

Speaking about the structural features of mechanical seals, they should be divided into several categories:

- Single.

The simplest type of mechanical seals for the pump. It is not suitable for liquids with the ability to crystallize, as it can quickly fail. It is an ideal option for pumping light petroleum products, some types of food liquids, creams and cosmetics, bitumen, fuel oil, oil.

The single mechanical seal has a long service life. However, there are several nuances for the operation of this particular product. All of them relate to the compatibility of the part with the pumped liquid, that is, compliance with the chemical composition and pumping temperature.

- Double.

A universal type of mechanical seals for the pump, which allows you to work with extremely toxic substances. It provides protection even from minimal leaks, therefore it is actively used in enterprises for pumping expensive pharmaceutical or cosmetic, dangerous, prone to crystallization, gaseous liquid.

The double mechanical seal for the pump has a longer service life, due to which it is often used in cases when the single model quickly wears out and loses its technical properties.

Varieties of double mechanical seals for the pump

There are three main designs in the range of double mechanical seals for the pump, which have their advantages and disadvantages. There are several types of details of such a model: back-to-back, tandem, face-to-face arrangements.

The back-to-back model assumes the installation of two parts of the seal opposite to each other inside the stuffing box. A feature of a part with such a design is its compact size, high level of performance and the possibility of simple alignment of sliding surfaces. Among the disadvantages, it is necessary to highlight the limited pressure and the possibility of internal fluid entering the pumped product during a breakdown.

The tandem model - is a design where two sets of seals are installed in series. It increases the level of reliability of the entire system. Among the advantages of this part: the availability of backup protection, the ability to work with abrasive fluids and use at high pressure (the pressure of the shut-off fluid must be lower than the pressure of the working medium).

"Face to face" - - has a simple design. However, the mechanical seal for pumps of this type does not provide a backup seal and has reduced reliability in comparison with other options.

When do you need to replace the mechanical seal for the pump?

There are several reasons for mechanical seal failures for the pump, leading to the need to replace the part. Among them it is necessary to highlight:

- Wear and tear;

- Incorrect product selection;

- Use in dry running when the model is not designed for this;

- Seal sticking;

- Incorrect installation of the product.

The wear of the mechanical seal for the pump occurs as a result of long-term operation of the product. This is a natural process, the onset of which can only be delayed by monitoring certain factors, such as high temperature or abrasive inclusions, the correctness of installation and selection of the model.

Incorrect product selection without analyzing the working environment leads to an acceleration of the wear process. The service life may decrease from several years to 3-6 months. To prevent this from happening, before choosing a mechanical seal for the pump, consult with professionals or contact us for qualified advice.

The use of the product during dry running increases the degree of wear of the product by as much as 20%. This can be provided with the correct installation of automation and regular air discharge from the pumping part of the device.

After a long downtime of the pump, parts of the mechanical seal may stick together or to the shaft, which leads to loss of operational properties. This can be prevented by scrolling the shaft during storage or using the built-in anti-sticking function.

Incorrect installation of the product leads not only to wear, but also to the complete failure of the pump. Use the services of professionals to create a good balancing of the impeller and comply with the rules for installing the mechanical seal.

Advantages of mechanical seals

Mechanical seals have many advantages over other means of sealing:

- Complete minimization of leakage;

- Low maintenance costs of the product;

- Possibility of use at high pressure;

- Use in an aggressive work environment.

How to choose a mechanical seal for the pump?

Choosing a mechanical seal for a pump without outside help is quite difficult. Therefore, we have a function «Order a consultation», as well as the ability to download table of analogues of seals from other manufacturers.

Mechanical seal for pump вis selected based on information about the properties of the liquid, pressure level, temperature, fluid characteristics, reliability and emission standards. With constant work with liquid, the part should not corrode, so choose options with special coatings or anti-corrosion materials.

Depending on the pressure, the type of balancing is selected, and the temperature affects the materials of the sealing parts.

Thus, the selection of the product should be carried out taking into account the pump model and the working environment (operating conditions). For example, if you work with liquids that are not prone to crystallization and expect a small budget, choose a single mechanical seal. In other cases, double models will suit you.