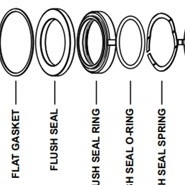

EBARA 3M pumps are mainly used for: water supply, pressure boosting, air conditioning, washing, irrigation, swimming pools, etc. In our case, the pump transfers brewing wort. A standard seal (GRAPHITE / CERAMIC / NBR) was used, which is not suitable for this medium (brewing wort). We replaced this seal with a BTS Engineering Ebara 3MHS mechanical shaft seal .

We offer the following...

Read more →

High-pressure pumps Fristam FPH and FPHP series are centrifugal, multistage pumps. They are designed for recirculation in reverse osmosis systems, with the possibility of adaptation to specific products, processes, and applications. FPH pumps can operate with inlet pressures up to 600 pounds per square inch, while FPHP models can operate up to 1000 pounds per square inch.

Fristam FPH...

Read more →

Single-stage end-suction pumps CNP series NISO, NIS, NISF are compact and easy to install. Thanks to the technological design, the bearing assembly with the impeller and sealing unit can be dismantled without disconnecting the pump casing from the pipelines. The pump is equipped as standard with a wear-resistant mechanical seal NISO-43/BSE4 728124298676 graphite/silicon carbide/EPDM.

In...

Read more →

Screw pumps Seepex MD series operate perfectly when pumping liquid and viscous media, as well as corrosive fluids containing solid particles, ensuring high dosing accuracy.

Seepex MD pumps are used in agriculture, the food industry, automotive manufacturing, chemical and biochemical processing, paper mills, distilleries, oil refining, and many other sectors.

These pumps are easy to...

Read more →

KSB Etaline — a monoblock pump in an “in-line” configuration.

Shaft seal version

E — External circulation;

F — External flushing;

S — Single mechanical seal with a vented chamber and rotating brake;

V — Single mechanical seal with a vented chamber.

Seal code: single mechanical seal

01 Q1Q1VGG 1 (ZN1181)

06 U3BEGG (shaft assembly 25, 35)...

Read more →

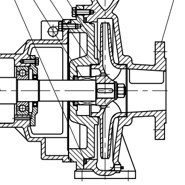

The Salvatore Robuschi RB (RBB-RBL-RBM) pumps are centrifugal pumps with a channel impeller designed according to ISO 5199 standards.

Various types of mechanical seals are used in these pumps in different configurations. The cylindrical seal chamber is built in accordance with EN 12756 standards. Single mechanical seals, double mechanical seals (tandem or back-to-back), or packing seals —...

Read more →

Wilo FA08.64E + FK17.1- 4/16K SN: 650217596 – a submersible pump for wastewater removal (including fecal matter and long-fibered and solid inclusions) used in water management, agriculture, construction, and industrial sectors, for water intake from rivers, reservoirs, and tanks.

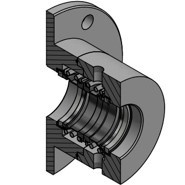

Seal for the liquid and motor chamber type "K": cartridge double seal with friction pairs on both the motor...

Read more →

MATRA S.p.a is a company that manufactures electric pumps: surface, borehole, and submersible, as well as pumping systems, including those for fire protection.

The company has been present on the international market for over 50 years. Its headquarters are located in Nonantola (MO), and the production plant is in Modena.

MATRA Spa is certified according to the UNI EN ISO 9001:2008...

Read more →

Pumps for industrial commercial swimming pools from the Spanish manufacturer Kripsol, MARFIL series MRF1500A 1500 rpm are centrifugal pumps with mixed flow, suitable for the drainage and pre-filtration of large volumes of water at low pressure. The pump housing and pre-filter housing are made of grey cast iron GG-25, the impellers are bronze, and the motor is protected to IP 55 standard,...

Read more →

The chemical cantilever pump type X is designed for pumping chemically active and neutral liquids at temperatures ranging from 233 to 393 K (from -40 to +120°C).

The type X pump is a centrifugal, horizontal, single-stage pump with a casing-mounted bearing. The shaft seal of the pump is either a double mechanical seal or a gland packing.

In our case, the X100-80-160 pump is used for...

Read more →

36 posts