Seals for agitators, hoppers and conveyors

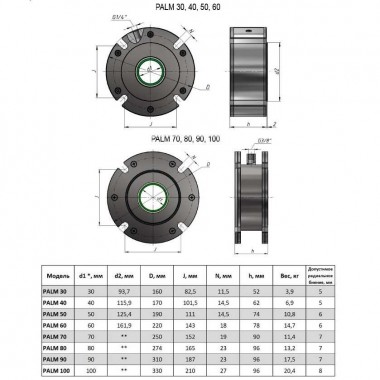

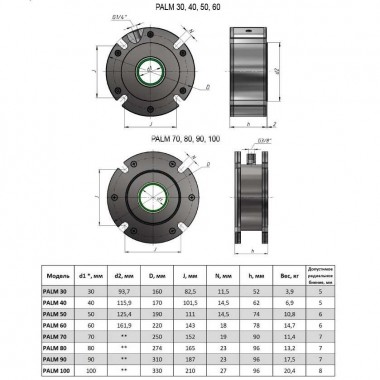

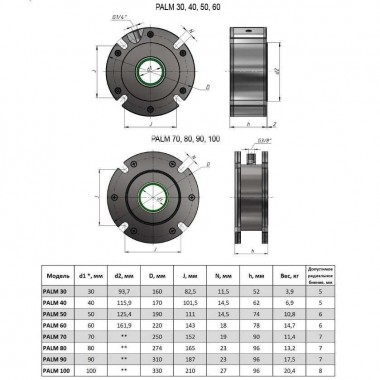

Sizes

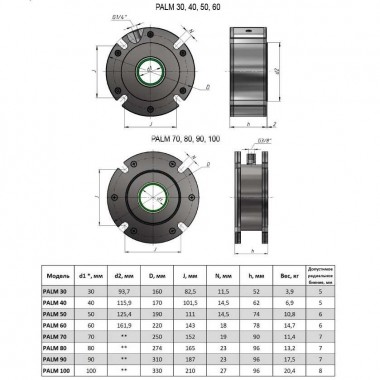

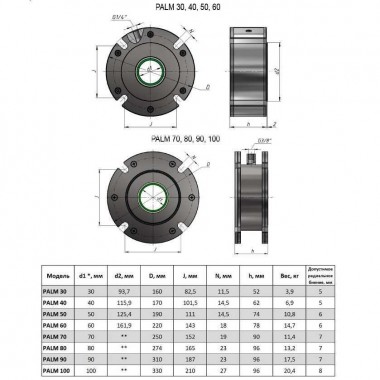

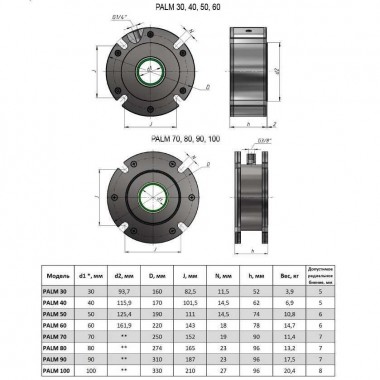

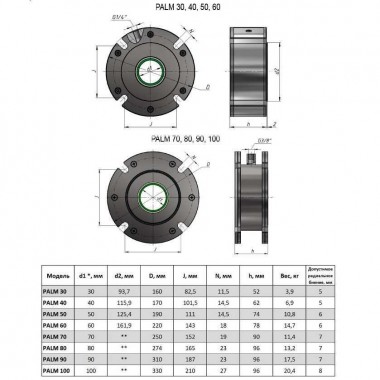

PALM 30, 40, 50, 60

PALM 70, 80, 90, 100

Dimensions in AISI version (stainless steel)

| Model | d1**, mm | d2, mm | D, mm | J, mm | N, mm | h, mm | The weight, kg | Permissible radial runout, mm |

| PALM 30 | 30 | 93,7 | 160 | 82,5 | 11,5 | 48 | 3,7 | 5 |

| PALM 40 | 40 | 115,9 | 170 | 101,5 | 14,5 | 52 | 5,9 | 5 |

| PALM 50 | 50 | 125,4 | 190 | 111 | 14,5 | 66 | 9,4 | 6 |

| PALM 60 | 60 | 161,9 | 220 | 143 | 18 | 77 | 12,8 | 6 |

| PALM 70 | 70 | ** | 250 | 152 | 19 | 86 | 11,4 | 7 |

| PALM 80 | 80 | ** | 274 | 165 | 23 | 86 | 13,7 | 7 |

| PALM 90 | 90 | ** | 310 | 187 | 23 | 96 | 18 | 7 |

| PALM 100 | 100 | ** | 330 | 210 | 27 | 96 | 20,4 | 8 |

* - for each standard size (model), you can choose the diameter of the sealed shaft in the range from +2 to -7 mm without changing the size of the housing

** - centering collar on request

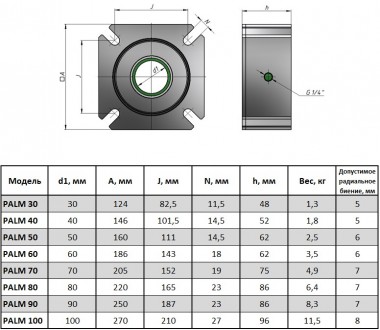

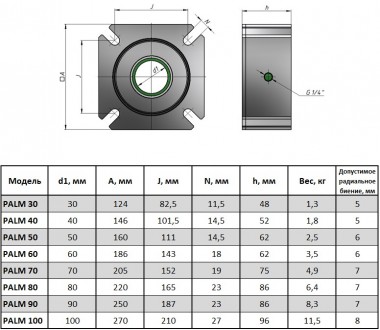

Dimensions in AL version (aluminum)

| Model | d1, mm | A, mm | J, mm | N, mm | h, mm | The weight, kg | Permissible radial runout, mm |

| PALM 30 | 30 | 124 | 82,5 | 11,5 | 48 | 1,3 | 5 |

| PALM 40 | 40 | 146 | 101,5 | 14,5 | 52 | 1,8 | 5 |

| PALM 50 | 50 | 160 | 111 | 14,5 | 62 | 2,5 | 6 |

| PALM 60 | 60 | 186 | 143 | 18 | 62 | 3,5 | 6 |

| PALM 70 | 70 | 205 | 152 | 19 | 75 | 4,9 | 7 |

| PALM 80 | 80 | 220 | 165 | 23 | 86 | 6,4 | 7 |

| PALM 90 | 90 | 250 | 187 | 23 | 86 | 8,3 | 7 |

| PALM 100 | 100 | 270 | 210 | 27 | 96 | 11,5 | 8 |

Purpose of the product

Seals of this type are designed for sealing the shafts of various types of equipment, such as agitators, screw and screw conveyors, dough mixers, chemical reactors, inclined screw conveyors, belt blenders, paddle mixers and dryers.

Seals are used in the transportation of dry powders, emulsions and suspensions in the food, pharmaceutical and chemical industries, where minimal maintenance costs are required.

This type of seal is an alternative to the lip seals and the classic stuffing box. The PALM seal does not have the disadvantages of both of the above types of seals, namely, increased requirements for the cleanliness of the shaft treatment at the sealing site, tolerances for radial runout or shaft misalignment, frequent maintenance, product leakage.

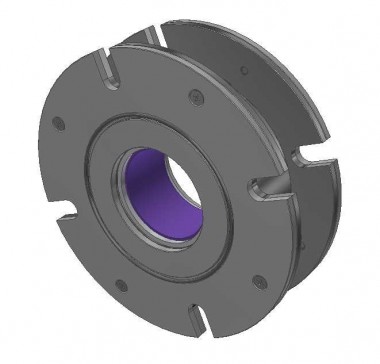

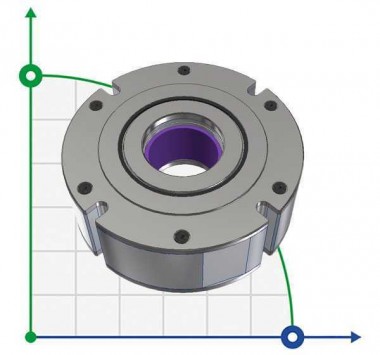

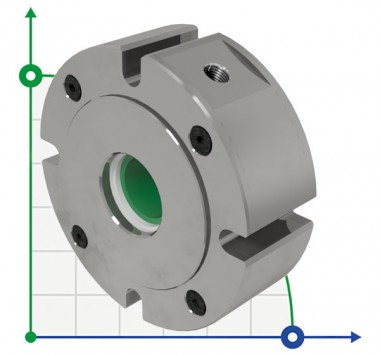

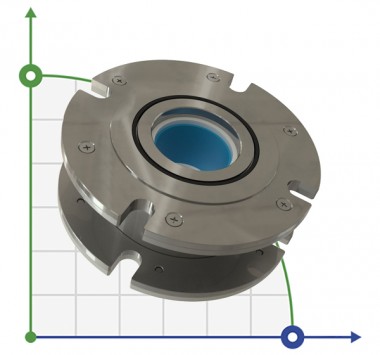

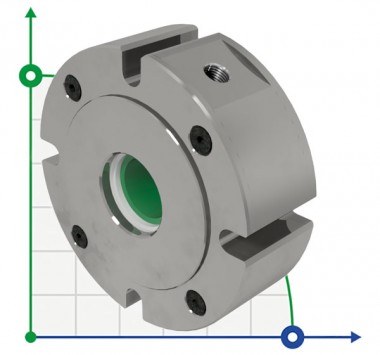

Device

The PALM seal is a dynamic sealing unit. The fixed housing contains an elastomeric sleeve, compressed with disks made of fluoroplast. The bushing rotates with the shaft in the seal housing, being in constant end contact with the sealing discs installed in the housing.

A sealing rubber O-ring is installed between the body of the seal itself and the wall of the container (hopper), which prevents the product from leaking through the gaps between the seal and the container body.

Thus, in the seal, the primary sealing of the shaft is carried out in three possible directions – leakage along the shaft, leakage between the seal body and the container body, leakage of the product between the sealing discs of the seal itself.

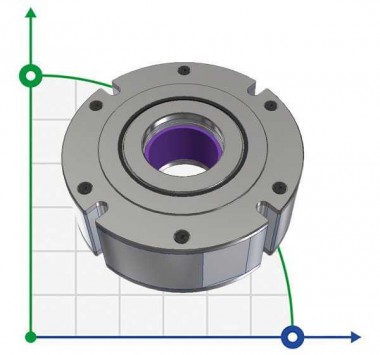

The dynamic action of the seal, namely the second stage of sealing, is based on the principle of purging (backing) the sealing chamber with compressed air.

On the seal body there is a connection for the supply of compressed air. The presence of excessive pressure in the inner cavity of the seal guarantees its normal operation and the absence of product leakage, even with significant wear of the sealing discs. The pressure of the air supplied to the seal must exceed the pressure in the container by 0.5-0.8 atm.

The sealing sleeve, rotating together with the shaft, can move in the radial direction without loss of sealing capacity.

This type of design allows you to maintain tightness with significant radial runouts of the shaft (depending on the model from 3 to 10 mm), and its distortions. For a general view of the seal and the installation diagram, see Fig. 1, fig. 2 (page 4)

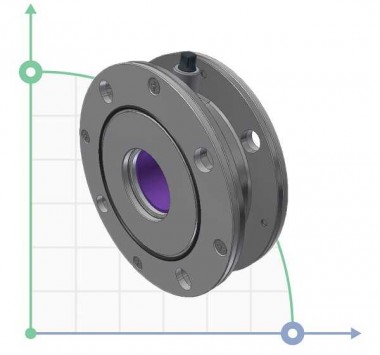

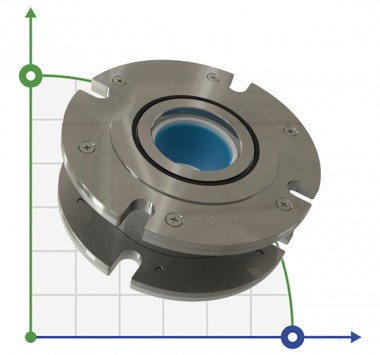

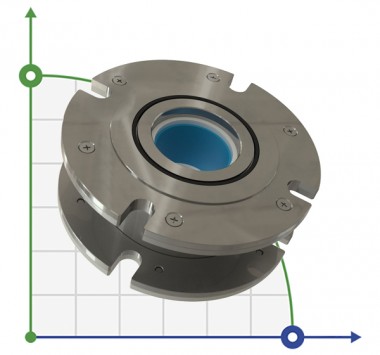

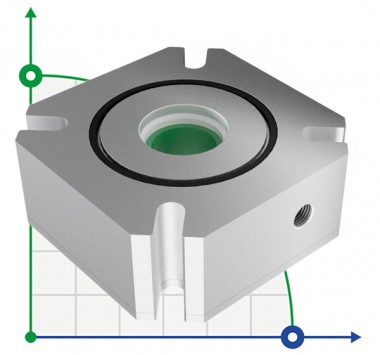

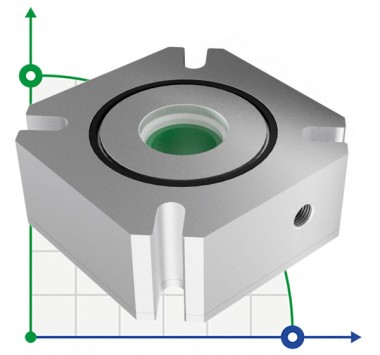

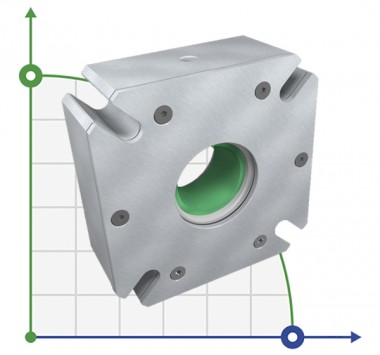

General view of the PALM seal

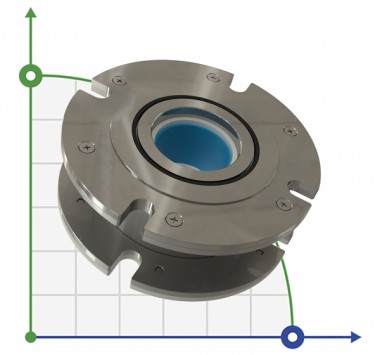

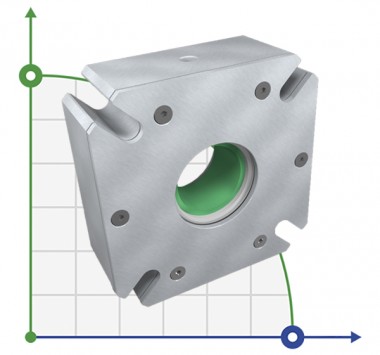

The scheme of the seal setup

Technical specifications and materials

Specifications

- The maximum speed of rotation of the shaft is up to 200 rpm (depending on the diameter of the seal)

- The maximum temperature is 120 ... 150 Deg. C (depending on the material of the sealing sleeve)

- Permissible radial displacement of the shaft – 3 ... 10 mm (depending on the diameter of the seal)

- Permissible shaft misalignment-2..4 deg

- Maximum pressure-6 bar

- Permissible air leaks - from 20 to 80 l / min (depending on the degree of wear of the sealing discs)

- Type of lubricant-silicone grease (food grade or technical)

Marking of product

(1) Seal type (brand name)

(2) Standard size (model) - the nominal diameter of the sealed shaft d1 with the housing dimensions optimized for a standard housing bearing (see the section "Dimensions", page 8)

(3) The diameter of the sealed shaft - for each standard size is possible in the range from +2 to -7 mm without changing the size of the housing

(4) Seal housing material

(5) The material of the sealing sleeve

Materials

- Body

- S-stainless steel AISI 304 (12X18H10T)

- C-structural steel (St. 3, St. 5, Steel 10, 20)

- A-aluminum alloy (D 16)

- Bushing

- E-EPDM (rubber mixture based on ethylene-propylene rubber)

- V-Viton (rubber mixture based on fluoro-rubber)

- N-NBR (rubber compound based on butadiene nitrile rubber)

Recommendations for installation and use

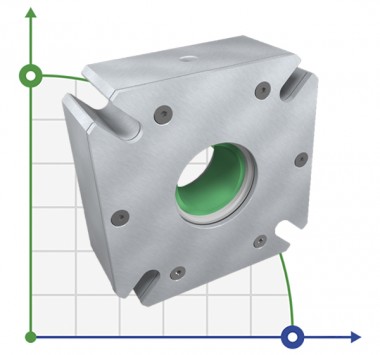

Ways to install the seal

There are two main ways to install the PALM type seal - installation between the wall of the machine body (agitator, conveyor) and the flanged shaft housing bearing (see Fig. 3).

Fig. 3

In this case, the seal is pressed by the bearing itself to the housing, and is held together with it by means of mounting pins or bolts.

This installation scheme is typical for shafts of relatively small diameter (up to 50 mm).

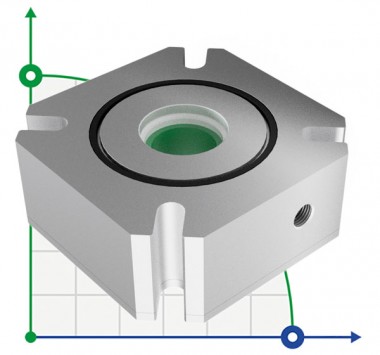

- the seal is installed separately from the bearing assembly, on the housing (wall) of the hopper or container through which the shaft passes (see Fig. 4)

Fig. 4

Recommendations for installation and use

This installation scheme is more typical for relatively large diameter shafts, due to the fact that the mounting of the housing bearings requires too much axial force. However, for vertical shafts, the use of body bearings large diameter is acceptable.

Installation recommendations

When installing the seal, lubricate the shaft with soapy water, silicone or ordinary water Between the container body (hopper) and the seal, install the sealing ring. O-ring (see Fig. 1, 2, page 4). The contact area must be sufficiently flat for the seal to fit securely to the housing.

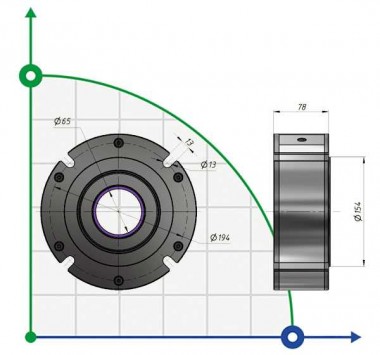

Secure the seal to the container body (wall) with pins or bolts according to the 1st or 2nd scheme (see Fig. 3, 4, page 6). The covers of the seal housings of 60 standard sizes, inclusive, have a centering collar (see Fig. 2, p. 4) under a standard housing bearing, for easy mounting (size d2, see "Dimensions", page 8)

This type of seal, due to its design features, does not require precise alignment of the shaft or bearing, so all models of seals can be installed in both recommended ways. Connect the compressed air supply line to the connection (see Fig. 1, p. 4), adjust the required air pressure value.

Recommendations for use

The seal can be used for pressure (up to 6 bar), non-pressure (under atmospheric pressure), and vacuum tanks ( up to -0.8 atm). When using the seal in open containers, purging with compressed air is desirable, but not mandatory. The use of compressed air significantly extends the service life of the seal.

In pressure tanks, the pressure of the air entering the seal must exceed the pressure in the tank by 0.5-0.8 bar. When using a seal on containers under vacuum, the compressed air supply connection should be closed with a plug.

The main mode of operation of the PALM type seal is operation without lubrication, with the use of compressed air purging. However, if the technological process allows for a slight penetration of grease into the product, it is possible to use an appropriate silicone lubricant, which will also significantly extend the service life of the seal and improve its performance.

The seal can be used for bulk, liquid and gaseous products, as well as for suspensions and emulsions in a wide range of density, viscosity and temperature.